Laboratory weathering - Artificial weathering

Benefit from our more than 10 years of experience in our accredited test laboratory on the subject of UV resistance/ageing of plastics and plastic products as a result of exposure to solar radiation, moisture/wetness and temperature. The three most important influencing factors are simulated with test equipment in order to answer the respective requirements and questions.

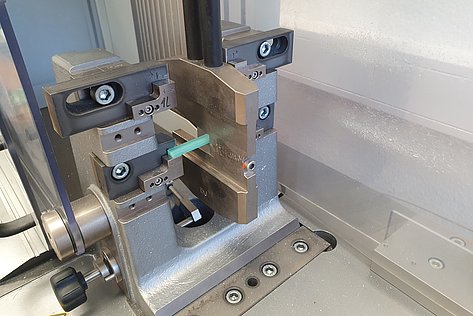

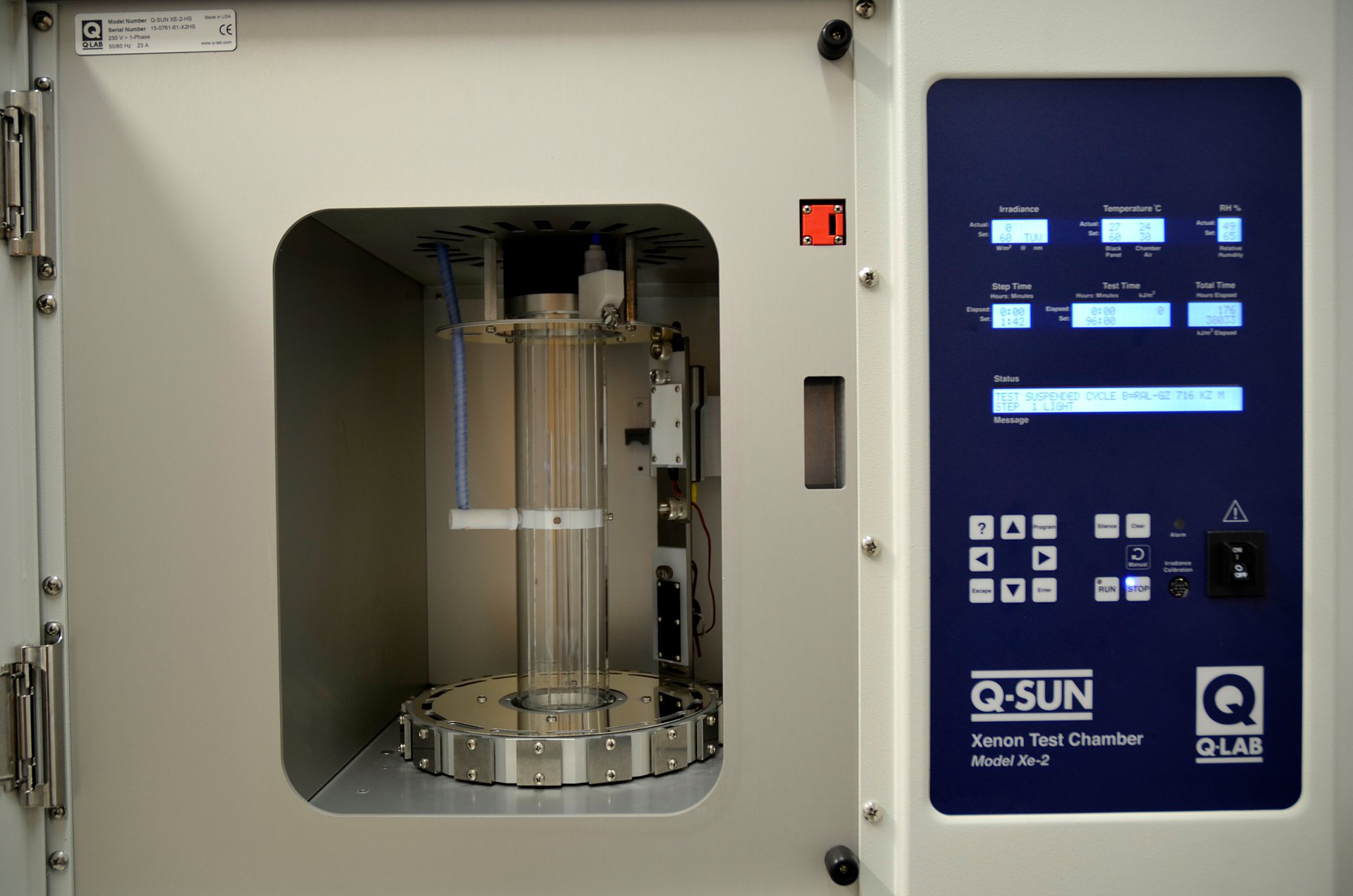

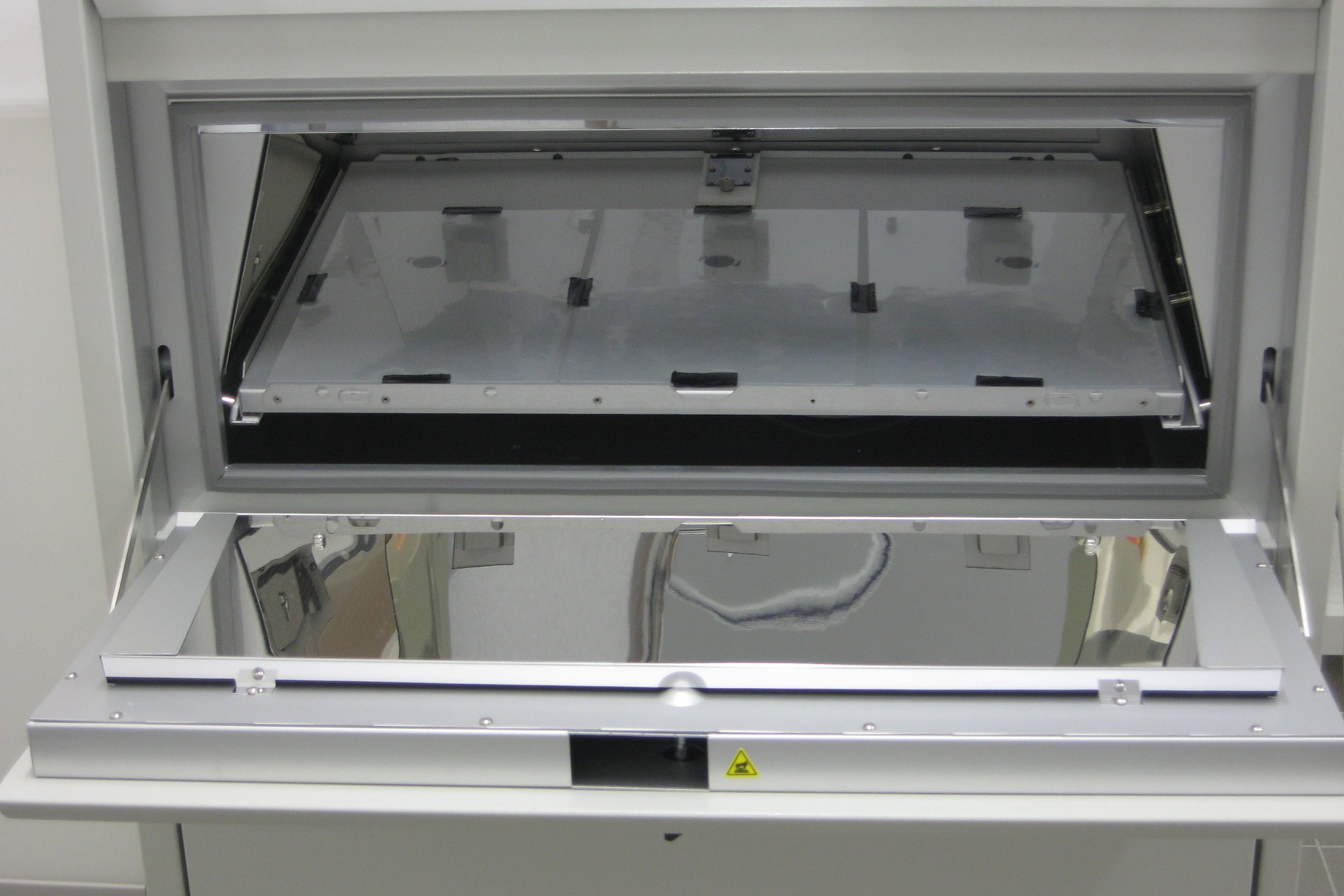

For laboratory weathering with filtered xenon arc radiation, a distinction is made between a testing device with a specimen holder that rotates around the xenon arc lamp (rotary drum testing device) and a device with a test chamber for holding three-dimensional larger components (flat bed device). We will be happy to advise you on which solution is the right one for your requirements.

Weathering conditions are regulated in national and international standards. Frequently requested standards are DIN EN ISO 4892-2, DIN EN ISO 16474-2, DIN EN 513 and ASTM G155 as well as the factory standards PV 3929 and PV 3930.

Fundamentals

Artificial weathering of plastics

Weathering is generally understood to be the effect of radiation, temperature, humidity/water, harmful gases and atmospheric components. A distinction is made between natural weathering (outdoor weathering) and artificial weathering (laboratory weathering).

Outdoor weathering takes place at fixed locations on earth, taking into account the given local environmental conditions, such as a maritime or industrial climate. Due to the long duration and the dependence of the results on the weathering location, i.e. the local climate, the season and the location on earth, investigations are carried out in the laboratory. Laboratory weathering has significant advantages in the evaluation of weathering resistance due to the possibility of realising a constant, reproducible irradiance, temperature, humidity and wetting periods/rain cycles. This makes it possible to make quick, location-independent statements. One speaks of artificial irradiation when the effect of water in the form of wetting periods or condensation is dispensed with.

In laboratory weathering, we also speak of determining weather fastness, weathering stability or light fastness. The light fastness is determined under pure irradiation.

Weathering with xenon arc lamps

For artificial weathering with xenon arc lamps, both rotary drum and flat bed test devices are available. A distinction is made with regard to the arrangement in the test chamber. In the rotary drum tester, the xenon arc lamp is arranged vertically and the specimen holders rotate around the lamp. The flatbed tester is characterised by a flat, level specimen chamber. This allows test specimens, plates as well as three-dimensional components to be examined. Irradiation is provided by three xenon arc lamps located in the ceiling of the chamber.

Technical equipment

Flatbed xenon arc tester – Q-Sun Xe-3-HSE (Fa. Q-Lab Corporation, USA)

- 3 xenon lamps with filter system

- Optical filters with spectral requirements for:

- Global radiation/sunlight (outdoor application) - Daylight-Q

- Global radiation behind window glass (indoor application) - Window-Q

- Control of relative humidity in the range 20 % to 95 %

- Indication of chamber temperature (air temperature)

- Spraying device

- Dimensions of the exposure area 45 cm x 72 cm

- three-dimensional samples / components

Standards

Accredited standards

- DIN EN 513

Kunststoffe – Profile auf Basis von Polyvinylchlorid (PVC) – Bestimmung der Wetterechtheit und Wetterbeständigkeit durch künstliche Bewitterung - DIN EN ISO 4892-1

Kunststoffe – Künstliches Bestrahlen oder Bewittern in Geräten – Teil 1: Allgemeine Anleitung - DIN EN ISO 4892-2

Kunststoffe – Künstliches Bestrahlen oder Bewittern in Geräten – Teil 2: Xenonbogenlampen C. UV-Fluoreszenzlampen

Other standards

- ASTM G151

Standard Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources - DIN EN ISO 16474-1

Beschichtungsstoffe – Künstliches Bestrahlen oder Bewittern in Geräten - Teil 1: Allgemeine Anleitung - ASTM G155

Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials - ASTM D2565

Standard Practice for Xenon-Arc Exposure of Plastics Intended for Outdoor Applications - ASTM D4459

Standard Practice for Xenon-Arc Exposure of Plastics Intended for Indoor Applications - ASTM D7869

Standard Practice for Xenon Arc Exposure Test with Enhanced Light and Water Exposure for Transportation Coatings - DIN 53387 (zurückgezogen)

Prüfung von Kunststoffen und Elastomeren – Künstliches Bewittern oder Bestrahlen in Geräten – Beanspruchung durch gefilterte Xenonbogenstrahlung - DIN EN 12608-1

Profile aus weichmacherfreiem Polyvinylchlorid (PVC-U) zur Herstellung von Fenstern und Türen – Klassifizierung, Anforderungen und Prüfverfahren - Teil 1: Nicht beschichtete PVC-U Profile mit hellen Oberflächen - DIN EN ISO 11341 (zurückgezogen)

Beschichtungsstoffe – Künstliches Bewittern und künstliches Bestrahlen – Beanspruchung durch gefilterte Xenonbogenstrahlung - DIN EN ISO 16474-2 (Ersatz für DIN EN ISO 11341)

Beschichtungsstoffe – Künstliches Bestrahlen oder Bewittern in Geräten - Teil 2: Xenonbogenlampen - DIN ISO 12040

Druck- und Reproduktionstechnik – Drucke und Druckfarben – Bestimmung der Lichtechtheit mit gefiltertem Xenon-Bogenlicht - ISO 4665

Elastomere, vulkanisiert oder thermoplastisch – Witterungsbeständigkeit

Company standards

- BMW Group – AA-0236

Kurzbewitterung im Xenontestgerät Farbbeständigkeit - General Motors – GMW 15188

Material Specification – Polyolefin Alloy – Weather Resistant, 1700 MPa Flexural Modulus, High Flow - Mercedes-Benz – DBL 5555

Fertigteile und Halbzeuge aus organischen Polymerwerkstoffen – Allgemeine Bedingungen und Prüfverfahren - Porsche – PPV 4014

Exterior – Bewitterung nichtmetallischer Werkstoffe – Prüfung im trocken-heißem Klima / im feucht-warmen Klima - Volkswagen AG – PV 3929

- Nichtmetallische Werkstoffe – Bewitterung in trocken-heißem Klima

- Volkswagen AG – PV 3930

Nichtmetallische Werkstoffe – Bewitterung in feucht-warmen Klima (Exterieur) - SAE J2527

Performance Based Standard for Accelerated Exposure of Automotive Exterior Materials Using a Controlled Irradiance Xenon-Arc Apparatus

Assessment possibilities of ageing

An evaluation of the ageing of plastic products as a result of laboratory weathering is often carried out by measuring the colour, comparing it visually with a reference sample and assessing the change in mechanical properties.

Dr.-Ing. Marcus Schoßig

Phone: +49 (0)3461 30889-53

Write e-mail

![[Translate to Englisch:] Laborbewitterung nach Norm](/fileadmin/inhalte/Kunststoffpruefung/Umweltsimulation/Laborbewitterung/2022-07-06_Alterung_von_Polymeren_-_Laborbewitterung_nach_Norm.jpg)

![Möglichkeiten der künstlichen Bewitterung [Translate to Englisch:] Möglichkeiten der künstlichen Bewitterung](/fileadmin/inhalte/Kunststoffpruefung/Umweltsimulation/Laborbewitterung/2022-07-06_Alterung_von_Polymeren_-_Moeglichkeiten_der_kuenstlichen_Bewitterung.jpg)