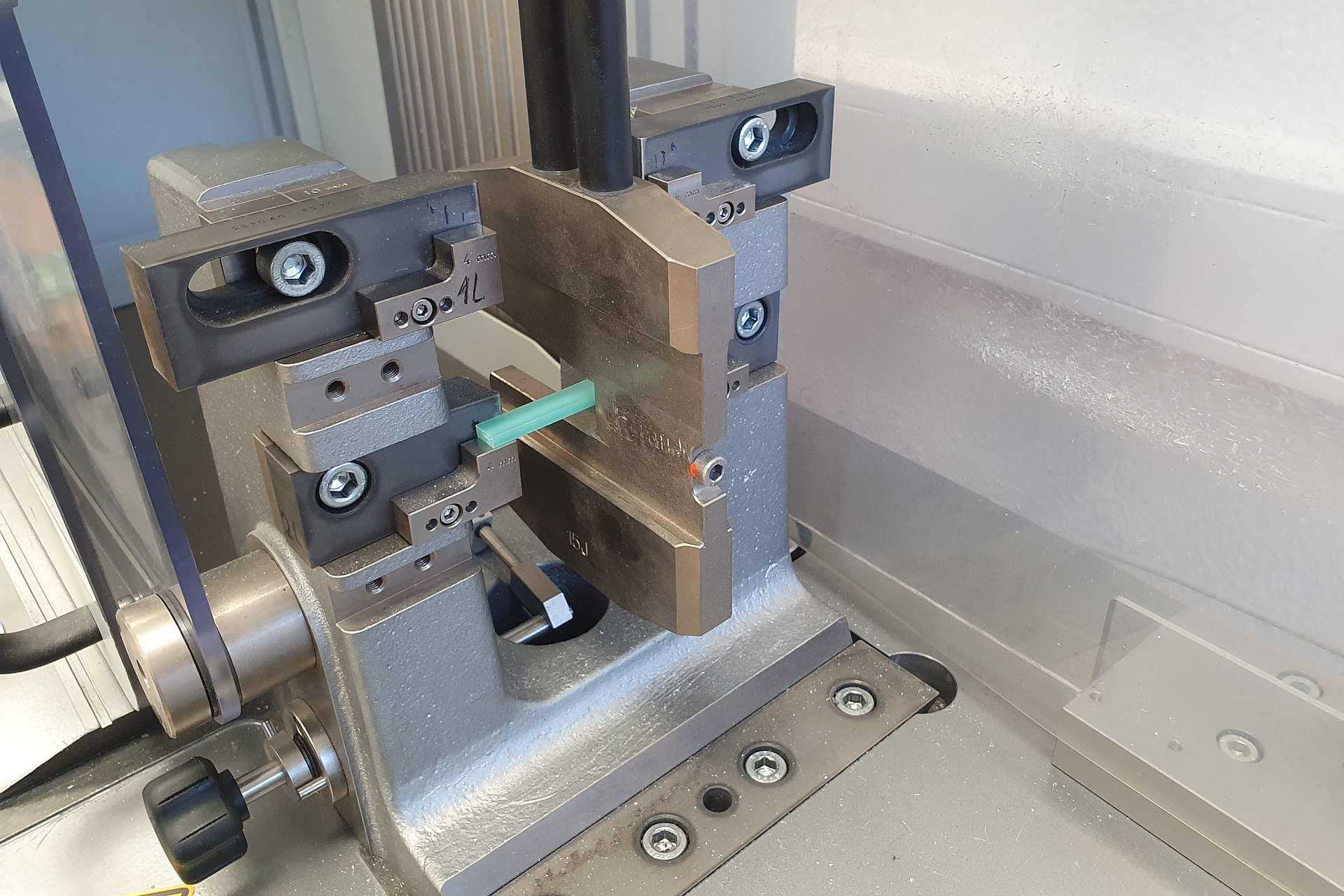

Impact and notched bar impact tests

In our accredited MPK testing laboratory, we can carry out the following tests for you with our modern pendulum impact testers:

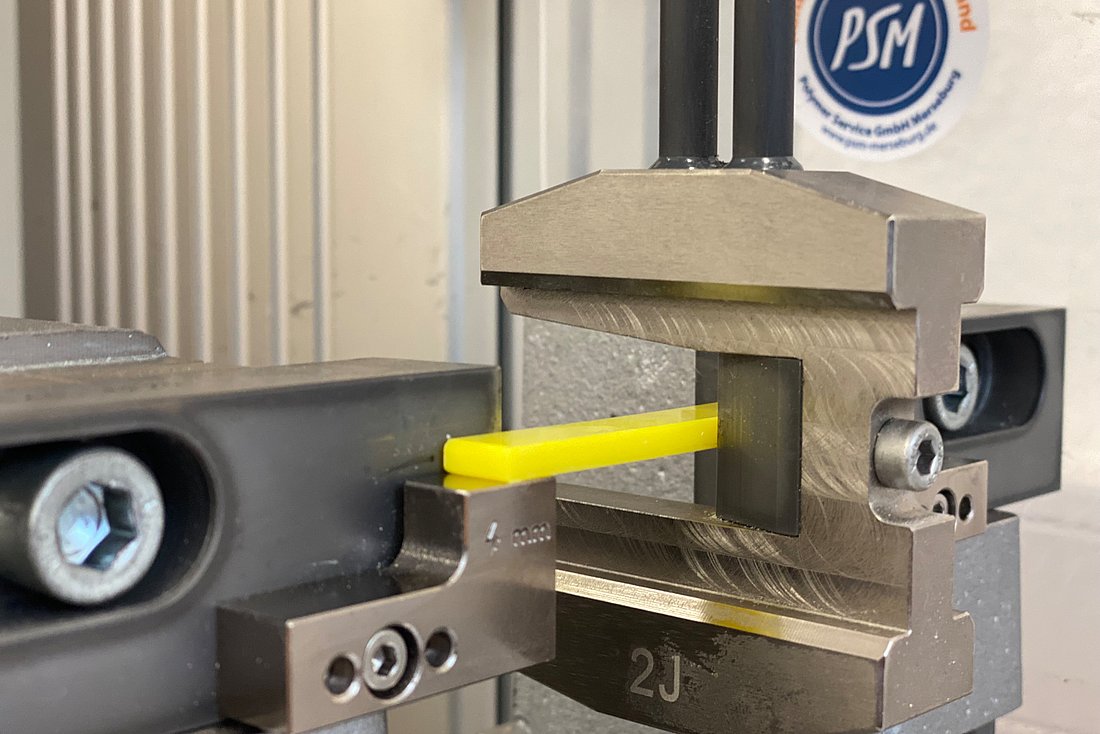

- Impact test and notched bar impact test according to Charpy, conventional and instrumented (according to DIN EN ISO 179-1 and -2)

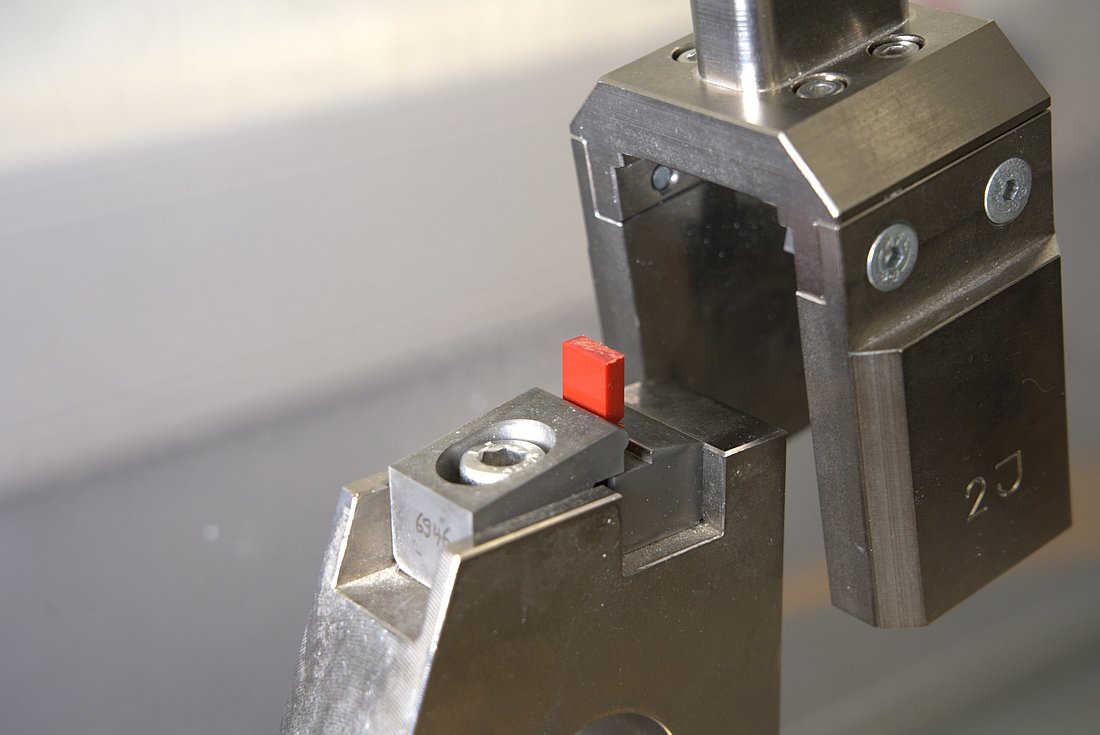

- Impact test and notched bar impact test according to Dynstat (according to DIN 53435)

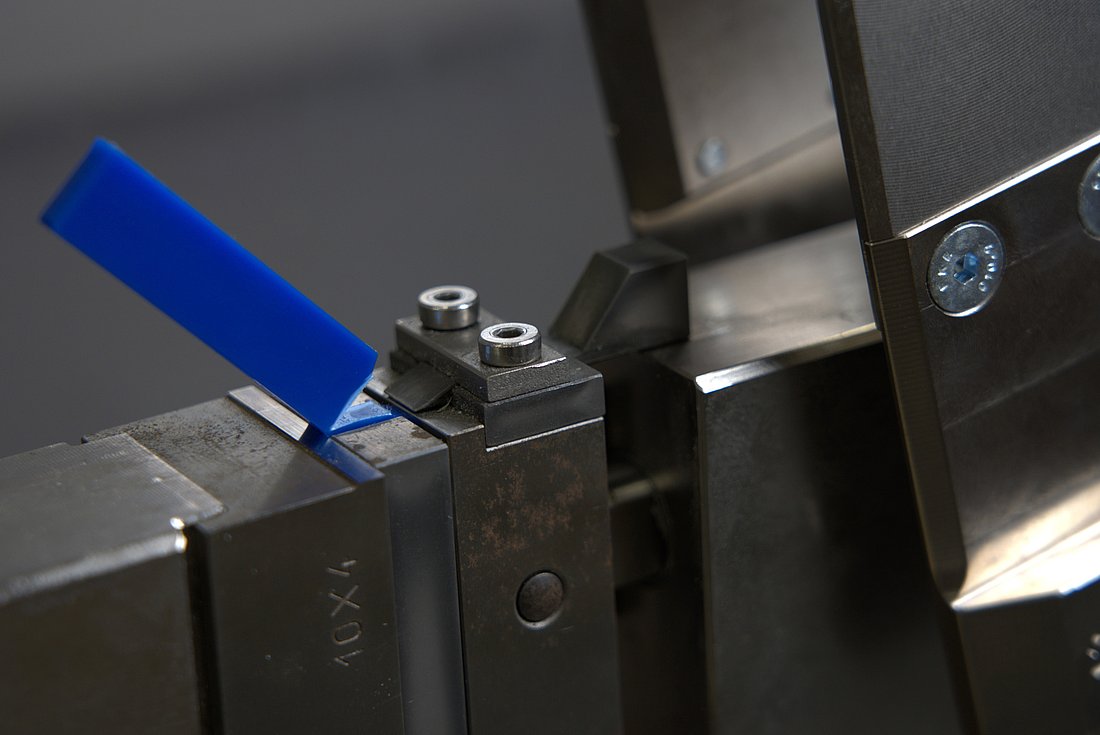

- Impact test and notched bar impact test according to Izod (according to DIN EN ISO 180)

Instrumented pendulum hammers can be used to record force-deflection diagrams according to DIN EN ISO 179-2, which allow further statements to be made on material behaviour.

Fundamentals

The Charpy (notch) impact test is standardised according to DIN EN ISO 179-1 and is used to assess the toughness behaviour of plastics under impact loading. In the Charpy arrangement in an impact bending test, the test specimen is positioned on two supports and subjected to an impact in the middle by a pendulum hammer of a pendulum impact tester.

Unnotched test specimens are used to determine the Charpy impact strength acU, while V-notched test specimens are used to determine the Charpy notched impact strength acN. The notch sensitivity can be calculated from the impact strength and notch impact strength.

The Dynstat impact test is used when only little material is available (e.g. taken from components). The test specimens have a size of 15 mm x 10 mm. The thickness should be between 1.2 mm to 4.5 mm. Both unnotched and notched can be tested.

The Dynstat impact strength adU or the Dynstat notched impact strength adA or adD are determined.

Our test laboratory can carry out all test variants specified in DIN 53435, including the new notch form A (V-notch).

The IZOD impact test is suitable for rigid thermoplastic injection moulding and extrusion compounds, thermoset materials and thermotropic liquid crystalline polymers as well as for filled and reinforced materials.

The IZOD impact strength aiU is determined when using unnotched test specimens or the IZOD notched impact strength aiN when using notched test specimens.

Sample preparation

Manufacture of the test specimen:

- Injection moulding

- Sawing, milling

Notch types:

- Charpy: V-notch type A (0.25 mm), type B (1.0 mm), type C (0.10 mm); U-notch (obsolete)

- Dynstat: U-notch 0.8 mm (type D), V-notch 0.25 mm (type A)

- Izod: Notches: V-notch type A (0.25 mm), type B (1.0 mm), type C (0.10 mm)

All test specimens can be weathered or exposed in our environmental simulation laboratory to investigate influencing factors such as the acting medium, temperature, solar radiation or a combined alternating stress of temperature and medium.

Test conditions

- Pendulum hammer with different impact energies:

- 0.5 J

- 1 J

- 2 J

- 4 J

- 7.5 J

- 15 J

- Test speed 2.9 m/s or 3.8 m/s

- edgewise or flatwise impact with different specimen dimensions

- test specimen type 1 (80 x 10 x 4) mm, type 2 or type 3

- Standard climate (23 °C, 50 % humidity)

- Temperature regime : from -70 °C to 95 °C (other temperatures on request)

- Recording and evaluation of impact force-deflection diagrams (instrumented test)

- Pendulum hammer with energy 2 J

- Test specimen geometry:

- Length (15±1) mm

- Width (10 ± 0,2) mm

- Thickness 1.2 mm to 4.5 mm.

- Standard climate (23 °C, 50 % humidity)

- Temperature regime: from -70 °C to 95 °C (other temperatures on request)

- Pendulum hammer with different energies:

- 1 J

- 2.75 J

- 5.5 J

- Test specimen type 80 mm x 10 mm x 4 mm

- Standard climate (23 °C, 50 % humidity)

- Temperature regime: from -70 °C to 95 °C (other temperatures on request)

Standards

Akkreditierte Normen:

- DIN EN ISO 179-1: Kunststoffe – Bestimmung der Charpy-Schlageigenschaften – Teil 1: Nicht instrumentierte Schlagzähigkeitsprüfung

- DIN EN ISO 179-2: Kunststoffe – Bestimmung der Charpy-Schlageigenschaften – Teil 2: Instrumentierte Schlagzähigkeitsprüfung

- DIN 53435: Prüfung von Kunststoffen – Biegeversuch und Schlagbiegeversuch an Dynstat-Probekörpern

- DIN EN ISO 180: Bestimmung der Izod-Schlagzähigkeit

weitere Normen:

- ASTM D 256: Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

Results

- Charpy unnotched impact strength acU

- Charpy notched impact strength acN

- Corrected impact energy Wc

- Notch sensitivity kZ

- Dynstat unnotched impact strength adU

- Dynstat notched impact strength adA und adD

- Izod unnotched impact strength aiU

- Izod notched impact strength aiN

- Impact energy W

- Maximum impact force FM

- Deflection at maximum impact force sM

- Energy up to maximum impact force WM

- Deflection at break sB

- Impact energy at break WB

Your standard is not listed or you would like to be tested according to other specifications? Please contact us.

Dipl.-Ing. Andreas Oluschinski

Phone: +49 (0)3461 30889-68

Write e-mail