Making heatseals and measurements of the seal strength

The determination of the peel force, also called seam strength or seal strength, determines the force required to peel two film strips that have been sealed together. The peel force generated can act as a parameter for the quality of a packaging line and provides information about the required sealing parameters.

Determining the peel force in the heat state allows the speed of a packaging line to be optimised. The sealing of two films is usually the last process step. In the industry, this parameter is also known as hot-tack. This determines the possible cycle of a processing line.

The films can be mono or multi-layer films (e.g. PE-LD, PE-LLD, PP, bo-PET, EVOH, EVA, etc.). Sealing between laminates with other materials (e.g. aluminium, cardboard) can also be investigated. The prerequisite for this is that at least one of the two films has a sealable inner layer.

Fundamentals

The determination of the peel force differs from the hot-tack method in the time of its determination. The peel force is only measured when the seam formed between two sealed films has cooled down. Due to possible relaxation processes, a storage time of about 7 - 10 days between sealing and determining the peel force is recommended.

As a rule, sealing parameters such as temperature and time are varied in order to determine the so-called sealing curve. The sealing curve gives important information about the behaviour of the examined materials under different sealing parameters, which can be simulated in the laboratory.

The examination "in the heat state" means that the measurement is carried out directly after the formation of a seam between two films sealed together, in contrast to the determination of the peel force after cooling.

As a rule, sealing parameters such as sealing temperature and sealing time are varied to determine the so-called sealing curve. The sealing curve provides important information about the behaviour of the examined materials under different sealing parameters, which can be simulated in the laboratory.

Technical equipment

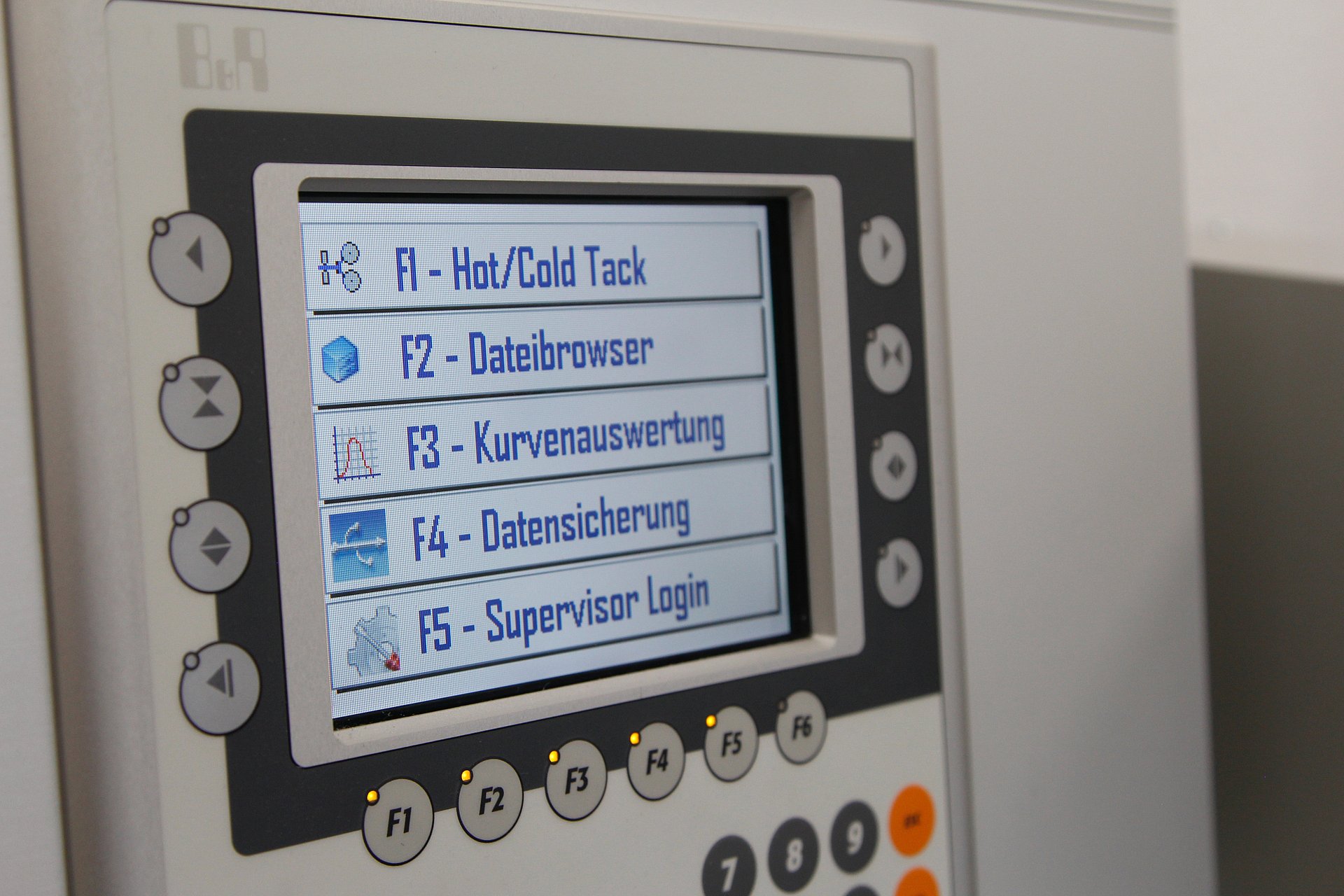

- Laboratory sealing device Kopp Labormaster HTC 3000

- Universal testing machine for determining the peel force after cooling down

- Pull-off speed and clamping length according to standard or agreement with customer

- Peel angle is 90°; the symmetry or asymmetry of the examined peel system must be taken into account

- Peel angle other than 90° is possible

- Determination of the peel strength directly after sealing

- Peel force measurable between 1.5 N and 200 N

- Specimen width: from 15 mm to 60 mm

Sample preparation

- Punching the foils to create strips of the desired width

- Storage in standard climate or other possible conditions

- Considering the orientation of the film, if necessary

Test conditions

- Variation of the sealing parameters:

- Temperature of the sealing bars: from 23 °C to 240 °C

- Sealing force: from 60 MPa to 1800 MPa (according to standard from 150 MPa to 300 MPa recommended)

- Sealing time: from 0.2 s

- Peel force measurable between 1.5 N to 200 N

- Sealing jaw geometry: flat, longitudinally grooved and waffle pattern

Standards

- DIN 55529:

Verpackung – Bestimmung der Siegelnahtfestigkeit von Siegelungen aus flexiblen Packstoffen - ASTM F 88/F 88-M09:

Standard Test Method for Seal Strength of Flexible Barrier Materials - ASTM F 1921/F 1921M-12:

Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible Web - ASTM F 2029-08:

Standard Practices for Making Heatseals for Determination of Heatsealability of Flexible Webs as Measured by Seal Strength

Results

- Peel strength

- Seal strength

- Seam strength

- Hot Tack

- Sealing curve

Dr. Katja Oßwald

Phone: +49 (0)3461 30889-72

Write e-mail