Peel test

Polymer Service GmbH Merseburg has many years of experience in the field of film testing. In cooperation with well-known film manufacturers, the test methods are constantly being further developed.

Various test methods are used in our MPK test laboratory to investigate the adhesion or cling behaviour of films. The T-peel test and the fixed-arm peel test are suitable for sealed films (e.g. from the food industry).

The cling test according to ASTM D 5458 is available to characterise the self-adhesion behaviour of stretch films. This method can be used to quantitatively evaluate the self-adhesion of a film (autoadhesion). The test involves measuring the cling force required to release a strip of film applied to the film with a defined force.

Fundamentals

![[Translate to Englisch:] Clingtest](/fileadmin/inhalte/Kunststoffpruefung/Mechanische_Pruefungen/Zugbeanspruchung/Peel-Clingtest/clingtest_2.jpg)

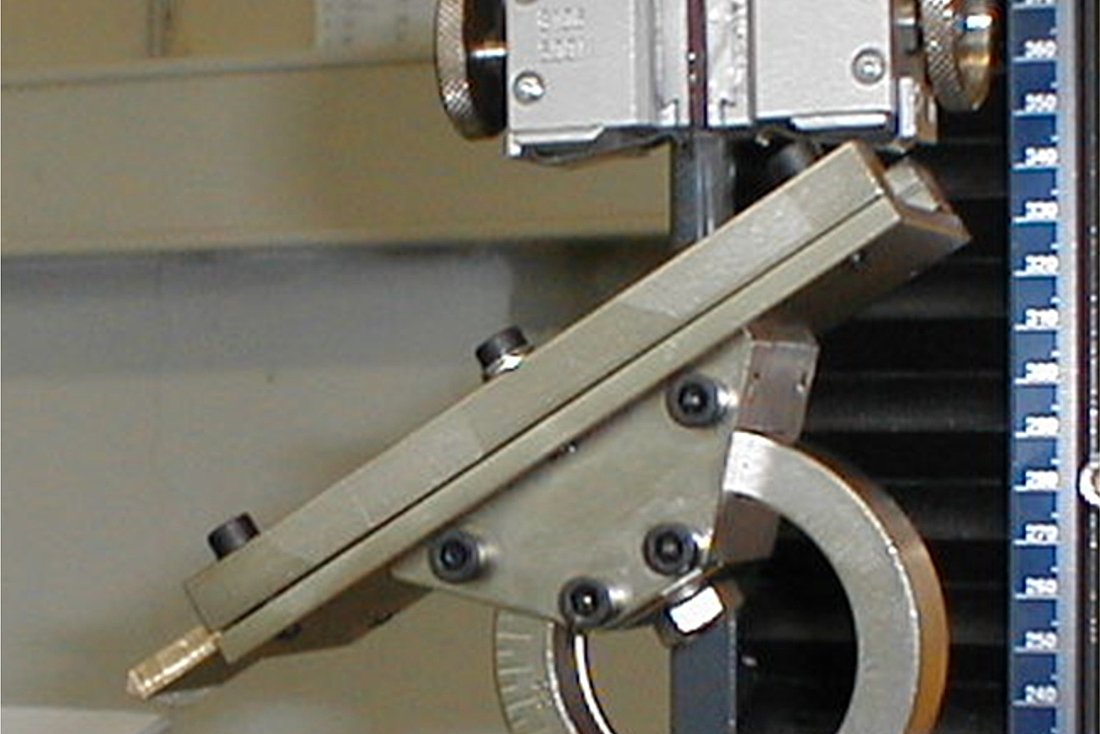

The cling test according to ASTM D 5458 is available to characterise the self-adhesion behaviour (autoadhesion) of stretch films. The test involves measuring the cling force required to release a strip of film applied to the film with a defined force. The testing device for performing the cling test is adapted to a universal testing machine with a suitable load cell.

The measuring principle is shown schematically in the figure. A 1 inch (approx. 25 mm) wide test piece of a film is adhered to another part of the same film, which is placed on the inclined plane with an angle of 20°. The strip of film to be peeled off is attached to a thread that is coupled to the crosshead. As soon as a crosshead movement occurs, the strip is detached. At the same time, the force and the distance are measured. According to ASTM D 5458, the end of the test is reached when 1 inch of the upper film has been detached up to the horizontal line (cling line).

The T-peel test is used to characterise the peel behaviour of peel systems. The designation "T" refers to the presence of two peel arms, each of which is bent through 90° during the peel test, resulting in a "T-shape". The T-peel test is performed on a universal testing machine.

During the peel test, a peel load-fracture path diagram is recorded, from which the peel load F can be taken as the application-related measured variable. For the fracture-mechanical characterisation of the peel process, the energy-determined parameter adhesive energy release rate is used.

The fixed-arm peel test is used to characterise the peel behaviour of peel systems as a function of the peel angle and is carried out in accordance with the ESIS TC4 standard proposal "Peel Testing of Flexible Laminates". The designation "fixed arm" means that one of the two peel arms has an unchangeable ("fixed") peel angle of 0°, while the peel angle of the second peel arm is variably adjustable. One peel arm of the test specimen is glued to a narrow brass plate, whereby the adhesive force must be many times greater than the expected peel force. After the specimen has been prepared, the brass plate is mounted in the fixed-arm peel tester and the remaining free peel arm is clamped in the clamping device of a universal testing machine. The peel angle is generally varied between 70° and 180°, whereby a peel angle of 70° represents the lowest limit for a meaningful examination of the peel properties of peel systems as a function of the peel angle, since for peel angles < 70° shear within the sealed seam is to be expected as the cause of failure. To realise a constant peel angle during the entire peel process, the fixed-arm peel tester can be moved sideways.

Sample preparation

- Die-cutting

- Sealing

- Ageing

- Tempering

- Preparation of test specimens from film roll

Test conditions

- Standard climate (23 °C, 50 % humidity)

Peel cling test

- Clingtest testing device according to ASTM D 5458

- Universal testing machine with 5 N load cell

Fixed-arm peel test

- Variation of angle between 70° and 180°

- Variation of peel speed

Standards

- ASTM D 5458: Bestimmung der Ablösefestigkeit von Streckfolien

Results

- Peel force F

- Cling value (N/mm²)

- Cling force FCling

- Total energy EG

Dr. Katja Oßwald

Phone: +49 (0)3461 30889-72

Write e-mail