Determination of ash

The ash content is determined by ashing procedure or filled plastics.

After the organic components have been burnt, the inorganic components can be determined.

The ash content is often determined according to DIN EN ISO 3451. Benefit from our many years of experience and contact us!

Fundamentals

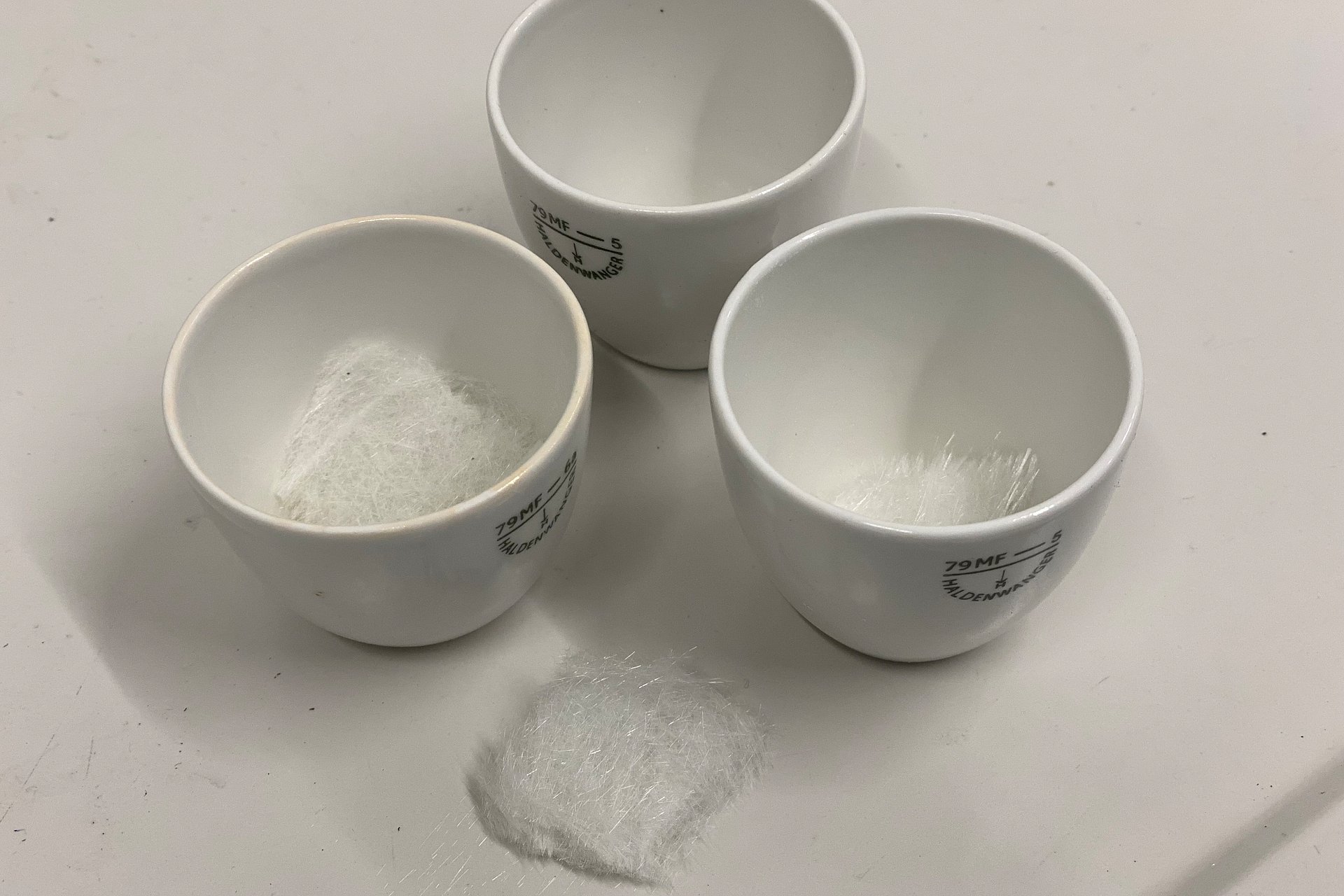

To carry out method A according to DIN EN ISO 3451, an analytical balance, a muffle furnace for temperatures up to 700 °C, a porcelain crucible with 20 ml capacity, a desiccator with CaCl2 filling and crucible tongs are required. Before weighing, the crucibles are cleaned and annealed.

The substance to be ashed is weighed into a crucible and annealed in a preheated muffle furnace until the mass is constant (at least 1 h), so that the entire organic content has evaporated. The residue must not show any dark colouring of charred substance. The crucible is removed from the furnace, cooled in the desiccator and then balanced.

The evaluation of the residue R or the loss on ignition P is done mathematically, the weight loss is given in mass percent.

Sample preparation

- Taking samples from

- Test specimens

- Components

- Sawing

- Punching

Test conditions

- Muffle furnace, as required at 600 °C, 750 °C, 850 ° or 950 °C

- Temperature continuously adjustable

- Analytical balance

- Porcelain crucible

- Desiccator with effective drying agent

- Method A - Direct calcination

Standards

- DIN EN ISO 1172:

Textilglasverstärkte Kunststoffe – Prepregs, Formmassen und Laminate – Bestimmung des Textilglas- und Mineralfüllstoffgehalts – Kalzinierungsverfahren - DIN EN ISO 3451:

Kunststoffe – Bestimmung der Asche- Teil 1: Allgemeine Grundlagen

- DIN EN 2331:

Luft- und Raumfahrt – Glasfilament-Prepreg – Prüfmethode zur Bestimmung des Harz- und Faseranteils sowie der flächenbezogenen Fasermasse

Prof. Dr. Ines Kotter

Phone: +49 (0)3461 30889-70

Write e-mail