Microscopy

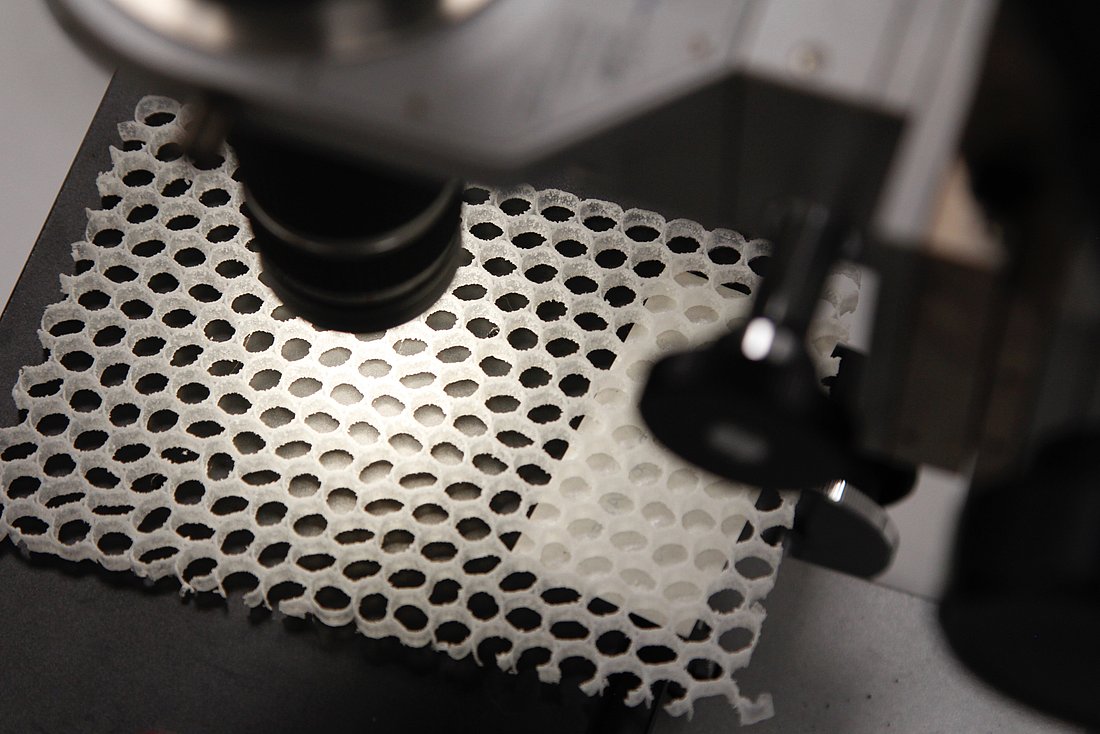

Light microscopy is suitable for visualising and quantifying structural elements up to a size of approx. 3 µm, such as layer structures, particles or fibres. Size distributions can be determined and surface structures can be visualised.

Digital microscopy is suitable for visualising surface structures with large asperities. Layer thicknesses and deformation structures can be measured. Fractography can be used to specify fracture surface features. Microscopy is an important component in the context of damage analysis. Due to the transportability of the device, measurements of complex, large components and in-situ images are possible.

Sample preparation

- Removal of samples from:

- Components

- Plates

- Test specimens

- Defective parts

- Embedding, grinding and polishing

Test conditions

- Upright research microscope and stereo microscope

- Maximum optical magnification: 500x

- Illumination and contrasting methods:

- Transmitted light, reflected light

- Dark field, bright field, polarization

- Digital magnification up to 1000x

- Large depth of field and 3D composition

- Illumination and contrasting methods:

- Transmitted light, side light, ring light

- Darkfield, brightfield, polarization, differential interference contrast (DIC)

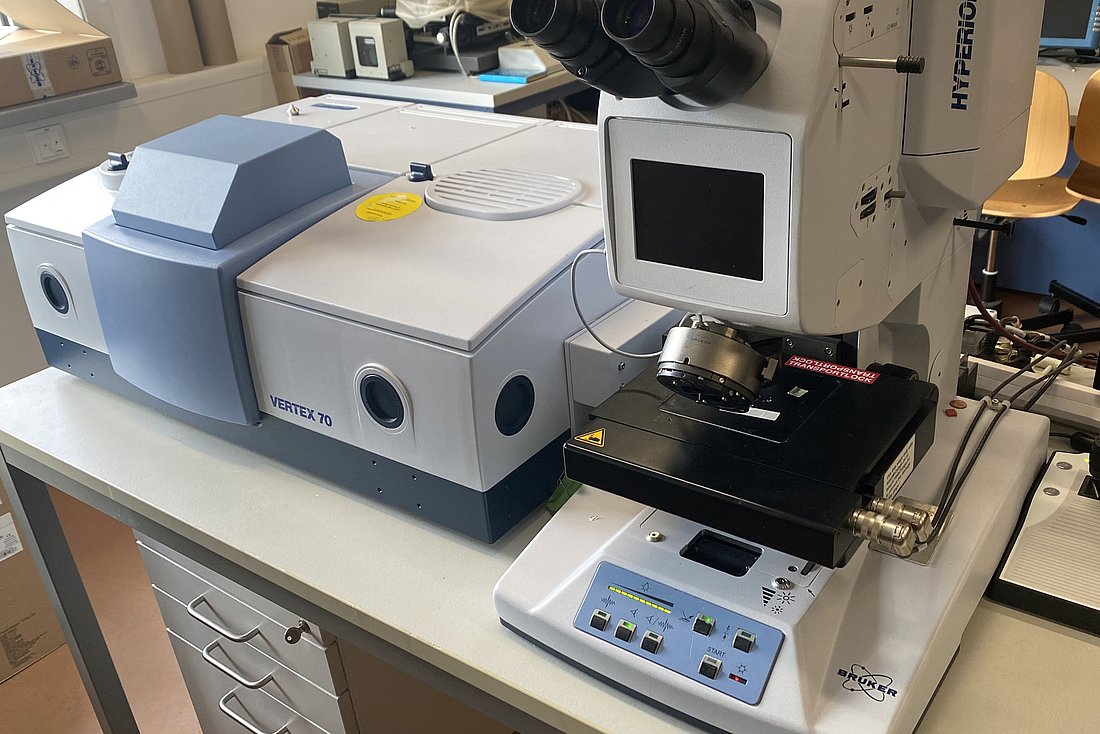

- IR-mikroscop Bruker Hyperion 2000

- 15x Cassegrin objective (transmission and reflection)

- 20x micro ATR objective (germanium crystal, diameter 100 µm)

- ATR imaging unit (germanium, diameter approx. 20 mm)

- 15x grazing-angle objective (grazing incidence)

- areas to be examined must be geometrically relatively flat

You can find more information on IR-microscopy here.

Results

- Layer structures

- Particle size

- Size distribution

- Fibre length distribution

- Aspect Ratio

- Histogram

- Surface structures

- Layer thickness

- Deformation structure

- Fractography

- 3D images

- Damage analysis

Dipl.-Wirt.-Ing. Anja Berthold

Phone: +49 (0)3461 30889-56

Write e-mail

Damage analysis

Prof. Dr. Ines Kotter

ö.b.u.v. Sachverständige (Thermoplaste/Duromere)

Phone: +49 (0)3461 30889-70

Write e-mail

Prof. Dr. Katrin Reincke

ö.b.u.v. Sachverständige (Elastomere/Folie)

Phone: +49 (0)3461 30889-55

Write e-mail