Fluorescent UV lamps

The decisive factor in the selection of a suitable test method is a sufficiently good simulation of the solar radiation by the radiation source used.

In the case of xenon arc lamps, this is achieved by using suitable filters. The UV and short-wave VIS range, which is photochemically effective for the ageing of plastics, is achieved by using fluorescent UV lamps as a radiation source.

Laboratory weathering with fluorescent UV lamps are particularly suitable for comparative tests and recommended for most plastics, textiles, pigments and UV stabilisers. Light fastness tests for simulating sunlight behind window glass can be carried out as well as irradiation of very stable materials by using lamps with shorter wavelengths.

Weathering conditions are regulated in national as well as international standards. Frequently requested standards are DIN EN ISO 4892-3, DIN EN ISO 16474-3 and ASTM G154.

Fundamentals

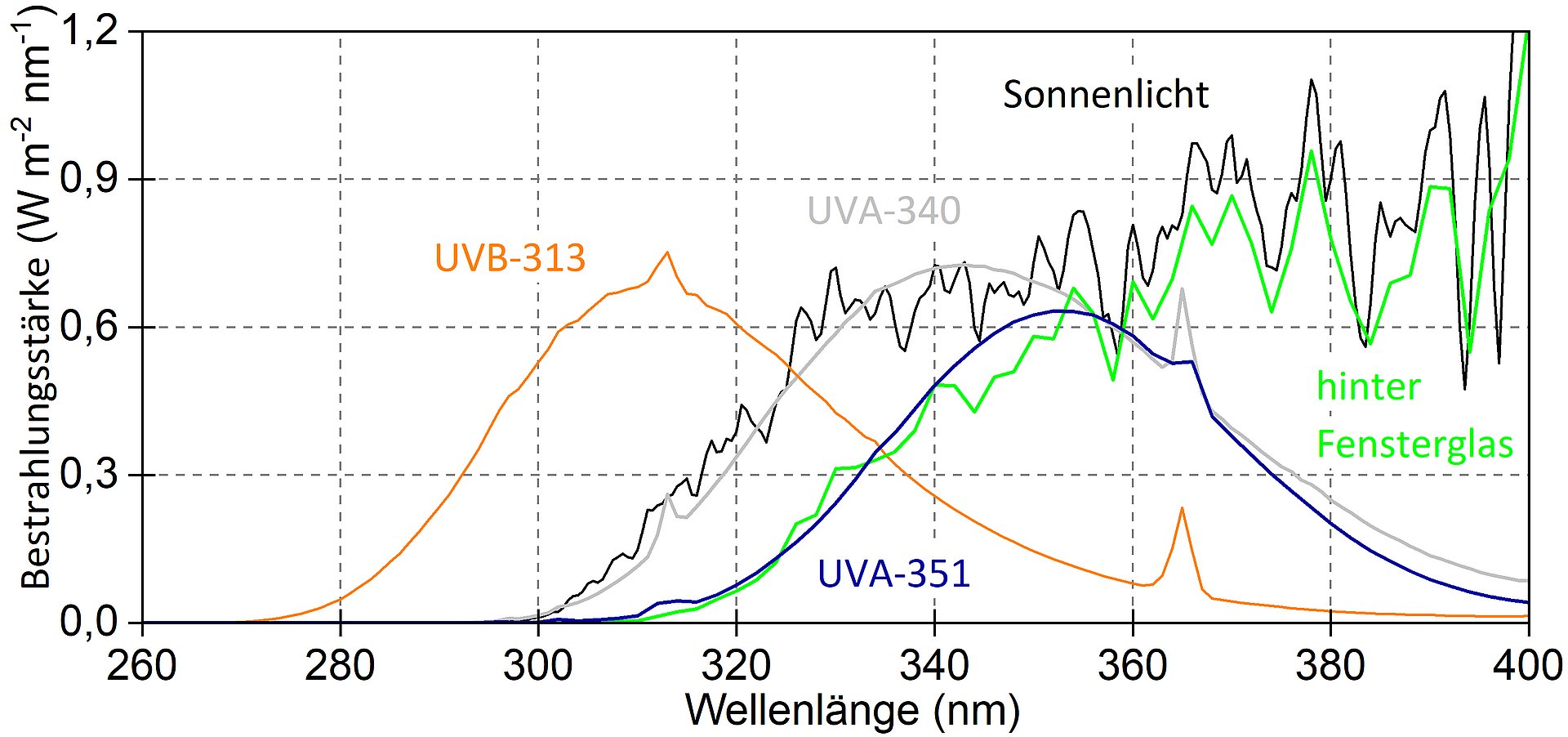

For the realisation of artificial weathering or irradiation carried out with fluorescent UV lamps, different lamps are used which have different radiation characteristics.

The short-wave UV range of sunlight is reached with the UVA-340 lamp in the wavelength range between 295 nm and 365 nm. The UVA-351 lamp simulates sunlight behind window glass. Both lamps show very good correspondence with the radiation characteristics of sunlight in outdoor weathering or behind window glass.

The UVB-313 lamps, on the other hand, also emit in the mid and far UV range and thus below the solar cut-off wavelength of 295 nm. These lamps are used in particular in the R&D sector, for quality control and for aerospace investigations.

Technical equipment

QUV accelerated weathering tester – QUV/spray (Q-Lab Corporation (USA))

- UV lamps with different spectral requirements for simulation:

- UVA-340 - sunlight in the wavelength range from 295 nm to 365 nm

- UVA-351 - UV component of sunlight behind window glass

- UVB-313 - Short-wave UV light, stronger than occurs on the earth's surface

- Condensation

- Water spray system

- Automatic control of irradiance SOLAR EYE

- Radiometer for calibrating the irradiance

- Test specimen holders for:

- Flat test specimens/plates/foils: 75 mm x 150 mm, clamped

- Multi-purpose test specimens: up to a length of 200 mm, clamped

- Three-dimensional component, application on a maximum surface of 495 mm x 324 mm and a thickness of 25 mm

Standards

Akkreditierte Normen

- DIN EN ISO 4892-1

Kunststoffe – Künstliches Bestrahlen oder Bewittern in Geräten – Teil 1: Allgemeine Anleitung - DIN EN ISO 4892-3

Kunststoffe – Künstliches Bestrahlen oder Bewittern in Geräten – Teil 3: UV-Leuchtstofflampen

Weitere Normen

- ASTM G151

Standard Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources - ASTM G154

- Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials

- ASTM D4329

Standard Practice for Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of Plastics - DIN EN ISO 11507 (zurückgezogen)

Beschichtungsstoffe – Beanspruchung von Beschichtungen durch künstliche Bewitterung – Beanspruchung durch fluoreszierende UV-Strahlung und Wasser - DIN EN ISO 16474-1

Beschichtungsstoffe – Künstliches Bestrahlen oder Bewittern in Geräten - Teil 1: Allgemeine Anleitung - DIN EN ISO 16474-3 (Ersatz für DIN EN ISO 11507)

- Beschichtungsstoffe – Künstliches Bestrahlen oder Bewittern in Geräten - Teil 3: UV-Fluoreszenzlampen

- SAE J2020

Accelerated Exposure of Automotive Exterior Materials using a Fluorescent UV and Condensation Apparatus

Dr.-Ing. Marcus Schoßig

Phone: +49 (0)3461 30889-53

Write e-mail