Creep tests on plastics

One challenge in estimating the service life of plastics is the time-dependent material behaviour, which already occurs at room temperature and is referred to as viscoelasticity (stress relaxation and strain relaxation - creep). Depending on the load level and application temperature, irreversible processes occur that can lead to breakage or impermissible deformation under constant long-term stress.

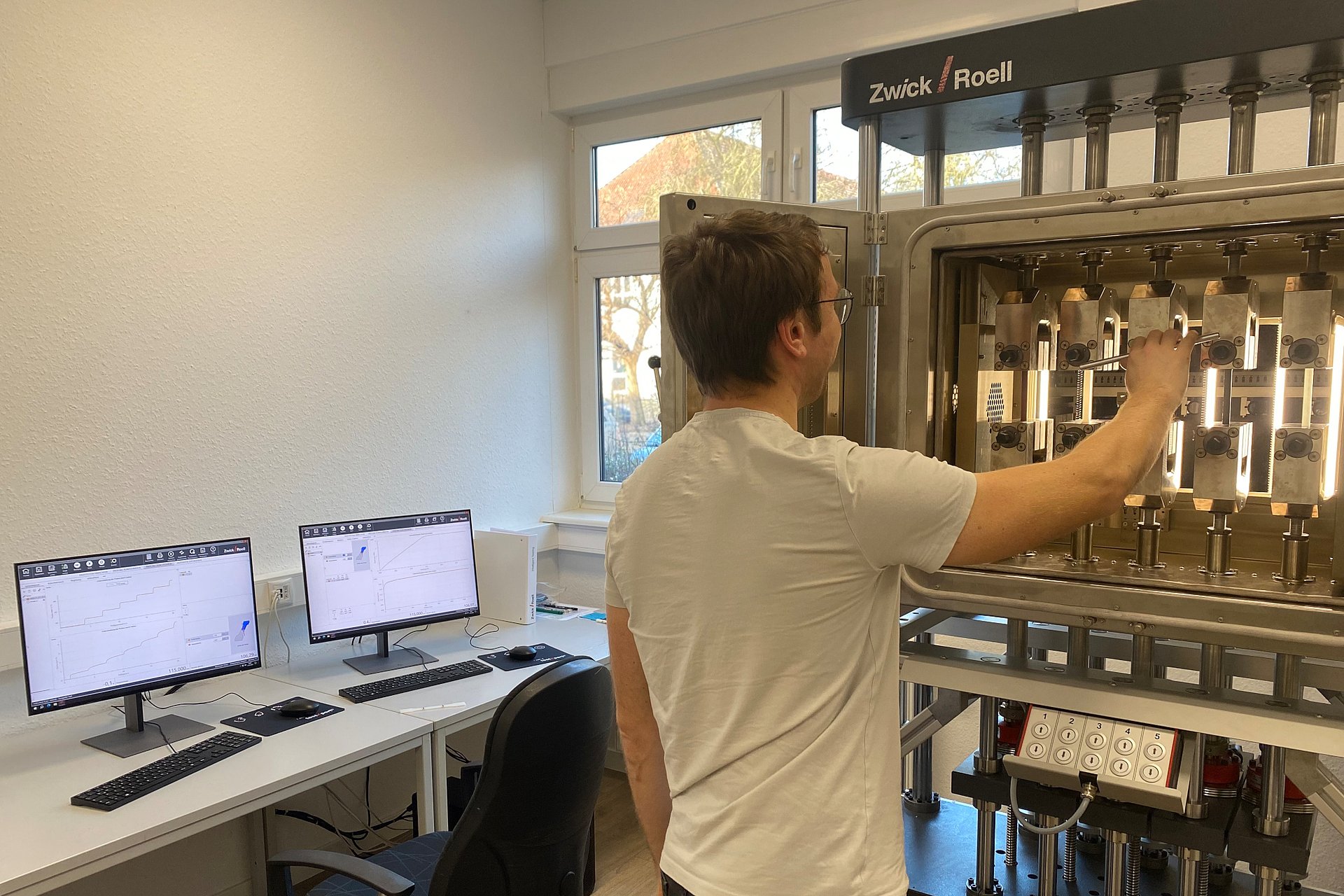

In our test laboratory, we can push your products to their limits in conventional creep tests. Our modern creep testing facility with five measuring stations is available for this purpose.

If you want to save time and money, then we are your competent partner for accelerated methods such as the SIM (Stepped Isothermal Method)! We will be happy to advise you.

Sample preparation

- Injection moulding

- Milling

- Punching

- Notches: one-sided for SENT test specimens (single edge notch tension) or two-sided for DENT test specimens (double edge notch tension) for fracture mechanics tests

- Exposure to media or artificial ageing

Test conditions

- Creep tests with constant load (retardation) and relaxation tests with constant strain in tensile loading

- Nominal force: 10 kN for 5 test axes (force measuring range from 20 N to 10 kN)

- Measuring point drive: Crosshead displacement 200 mm

- Test speed: 0.001 mm/h to 100 mm/min

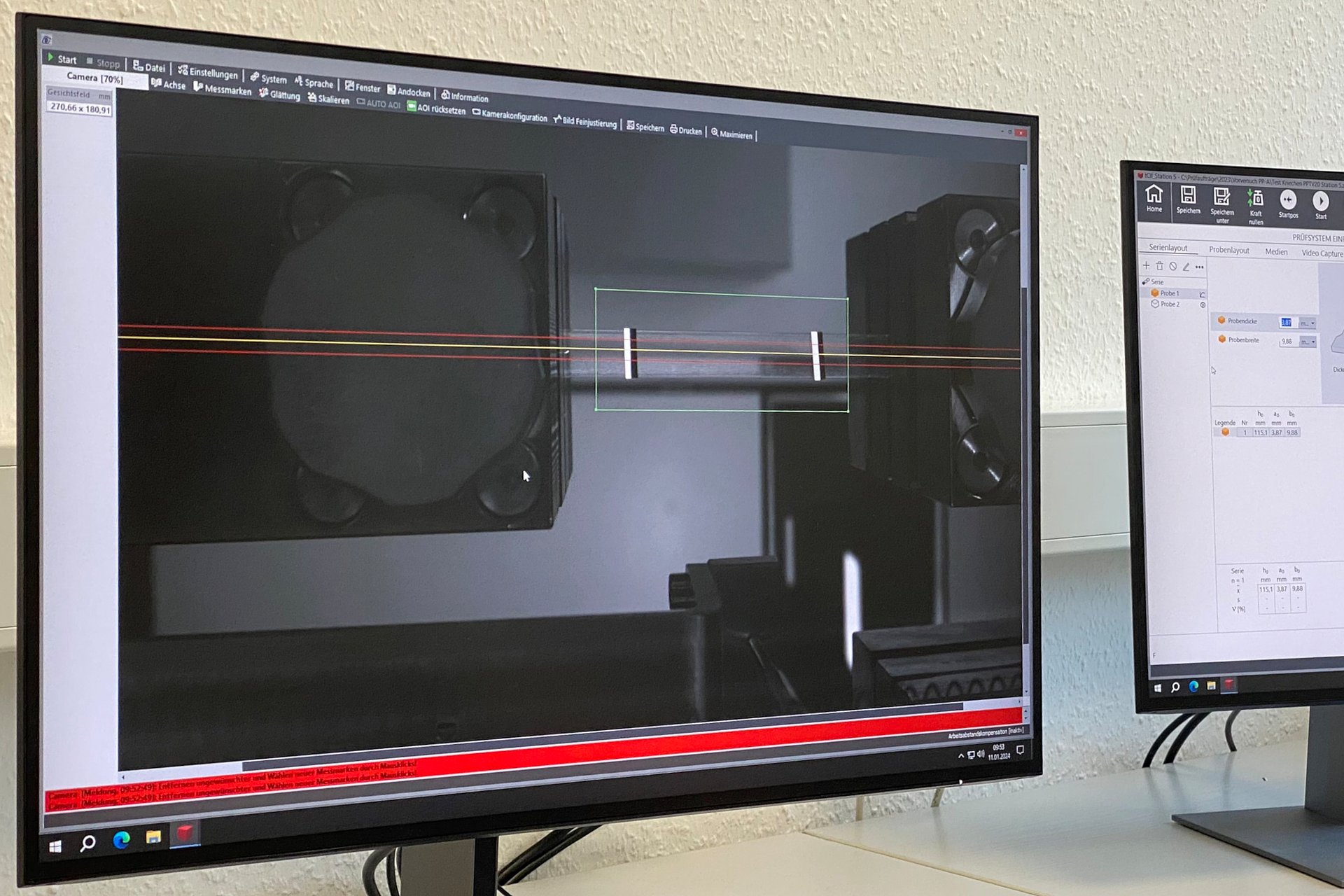

- Strain measurement: Video extensometer

- Temperature range: -40 °C to 250 °C

Standards

Normen

- DIN EN ISO 899-1: Kunststoffe – Bestimmung des Kriechverhaltens – Teil 1: Zeitstand-Zugversuch

- ASTM D 638: Standard Test Method for Tensile Properties of Plastics

Results

- Creep curves

- Creep modulus-time curves

- Isochronous stress-strain curves

- creep diagrams

- Fracture characteristics

- Relaxation curves

- Relaxation modulus-time curves

Contact

Dipl.-Wirt.-Ing. Anja Berthold

Phone: +49 (0)3461 30889-56

Write e-mail