Stability against stress cracking

Stress cracking, also called environmental stress cracking (ESC), is a physical ageing of plastics under medial stress. If chemical ageing occurs during medial stress, it is also referred to as stress corrosion cracking (SCC).

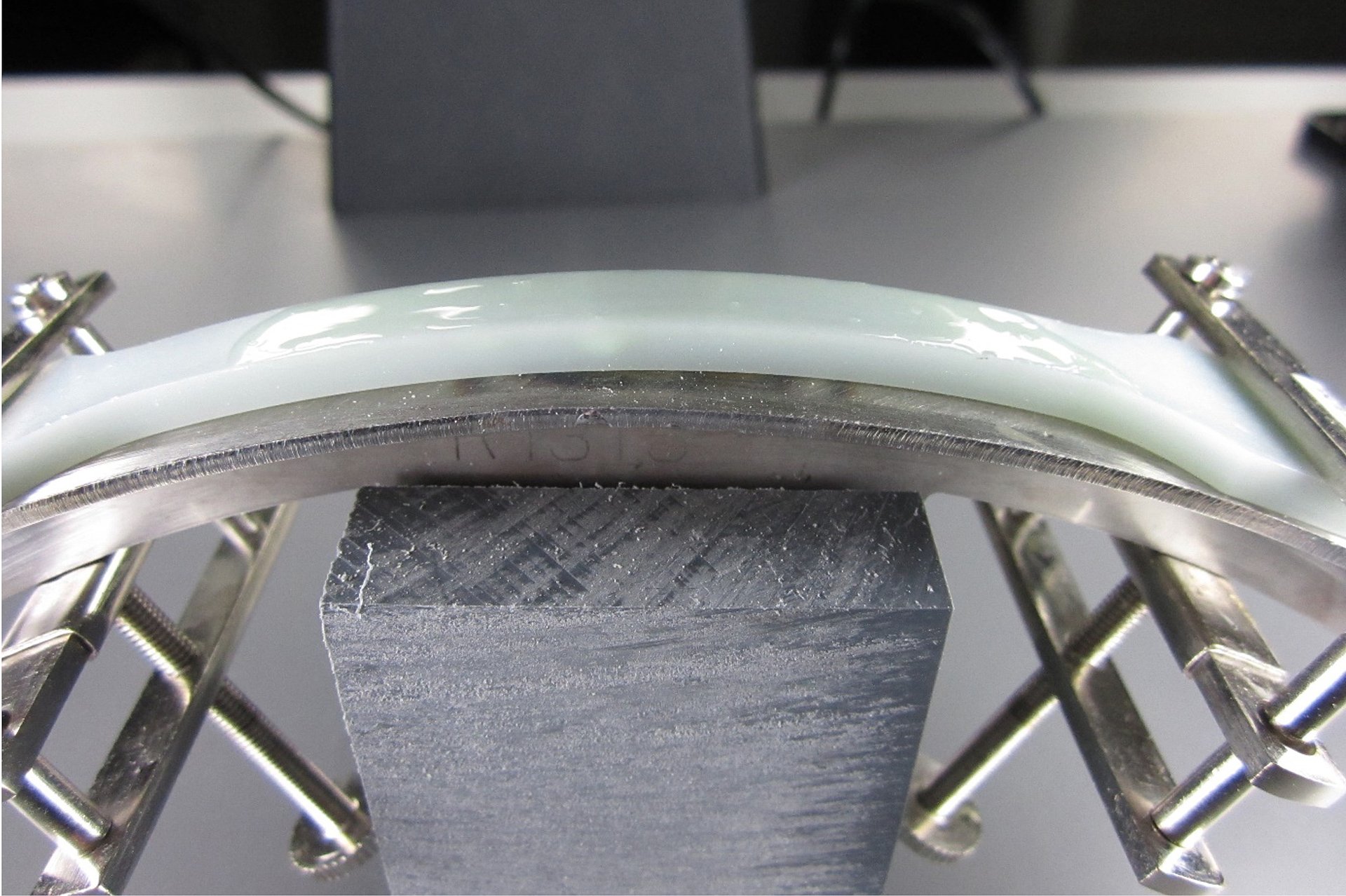

A typical method for determining stress cracking resistance is the bend strip method. Here, test specimens, preferably of type 1A according to DIN EN ISO 527, are fixed on bending templates with different radii of curvature. The edge fibre elongation is usually between 0 % (reference) and 2 % edge fibre elongation. These templates are either immersed in the medium or only the fixed test specimens are coated or sprayed with the medium.

Typical media for an ageing or stress crack resistance test can be washing lyes, oils, greases, cleaning agents, paints, varnishes or similar.

Since every combination of plastic, medium, temperature, ageing time and external stress is individual, we will be happy to advise you on your specific application.

Fundamentals

The stability of polymer materials against media is very strongly dependent on the type, structure and composition of the plastics. In addition, the media stability is influenced by the formation of internal stresses during processing and the ageing temperature.

When testing the stability of plastics, a distinction is made between stability testing without the application of an additional external stress (ageing, immersion test) and with the application of an additional external, mechanical stress (stress cracking resistance, stress corrosion cracking).

Ageing without external stress can be carried out in the medium, at elevated temperature, in water vapour, in water, with a cyclical alternating stress of temperature and humidity or also at standard climate. We have compiled details of all possible in-house variants for you under the term ageing.

Sample preparation

- Fixing the test specimens in the medium

- Fixing on bend strips

Test conditions

- (Regular) change of medium

- Brushing or spraying of the test specimens

- Individual coordination of:

- Medium

- Temperature

- Exposure duration (total and intermediate measuring points)

- external stress

- Indicator test

- Coordination of test specimen geometry and number

Standards

- DIN EN ISO 22088:

Kunststoffe – Bestimmung der Beständigkeit gegen umgebungsbedingte Spannungsrissbildung (ESC)- Teil 3: Biegestreifenverfahren

Es können sowohl weitere Normen als auch individuelle Liefervorschriften umgesetzt werden.

Assessment options

To characterise the ageing and the change in properties due to ageing, indicator tests such as the tensile or bending test are usually carried out on unloaded reference test specimens and the aged test specimens. An optical and microscopic observation as well as colour and gloss measurements usually accompany the tests.

Dipl.-Ing. Heidrun Müller

Phone: +49 (0)3461 30889-80

Write e-mail