Heat distortion temperature – HDT and Vicat

With our brand new Amsler HDT/Vicat Allround 6-300 from Zwick/Roell, we can quickly and reliably characterise the heat deflection temperature of plastics for you in our accredited testing laboratory.

We use a high-temperature-stable silicone oil so that we can determine Vicat softening temperatures (VST) and heat deflection temperatures (HDT) up to a temperature of 300°C in accordance with the standards.

Contact us, our motivated team will be happy to advise you!

Fundamentals

Due to their comparatively low temperature resistance, plastics are limited in their use at higher temperatures. It is therefore all the more important to know the temperature range under which a plastic component can be used under certain operating conditions and stresses.

During the test, the measured displacement and temperature are continuously plotted as a function of the test time, so that the indentation or deflection behaviour can be followed throughout the experiment.

Methodologically, the determination of the heat deflection temperature and the Vicat softening temperature leads to different results.

To determine the heat deflection temperature HDT, the test specimens are subjected to a constant flexural stress in a three-point flexural arrangement and heated in an oil bath until a defined edge fibre elongation is reached. The temperature at which the defined edge fibre elongation is reached is given as the heat deflection temperature HDT.

Depending on the material and the intended use of the plastic, three different bending stresses are realised - 1.8 MPa (HDT A), 0.45 MPa (HDT B) and 8 MPa (HDT C).

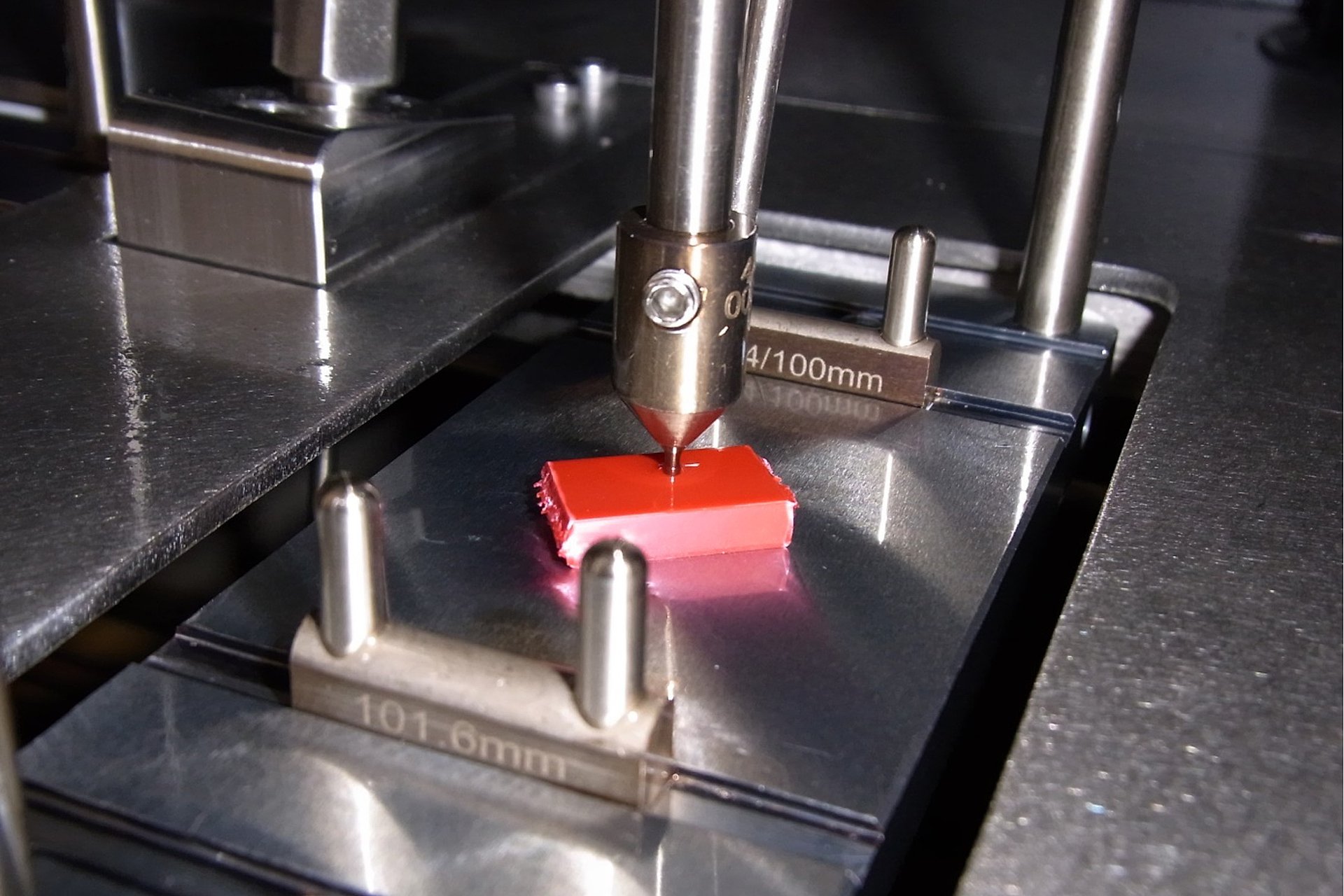

The Vicat softening temperature is reached when a flat needle with a diameter of 1 mm² penetrates one millimetre deep into a plane-parallel test specimen. A force of 10 N or 50 N is applied to the needle while the oil bath is heated at a rate of 50 K/h or 120 K/h respectively.

Technical equipment

- Amsler HDT/Vicat Allround tester (Zwick/Roell, Ulm)

- automatically controlled test procedure

- 3 measuring stations

- Testing in the temperature range from room temperature to 300 °C

- Heating in a silicone oil bath

- different weight sets

- 3 support distances: 64 mm, 100 mm, 101.6 mm

Sample preparation

- Removal of specimens from:

- Multi purpose specimens

- Sheets

- Components

- Specimen dimensions:

- for HDT preferred 80 mm x 10 mm x 4 mm (L x W x H)

- for Vicat preferred 10 mm x 10 mm x 3-6.5 mm (L x W x H) or 10 mm diameter

- plane-parallel surfaces, burr-free

- Stacking of specimens, if necessary (maximum three pieces)

Test conditions

- Procedure A, B and C for the determination of HDT

- Methods A50, A120, B50 and B120 for the determination of the VICAT softening temperature

- Load 10 N and 50 N

- Heating rate 50 K/h and 120 K/h

Standards

Akkreditierte Normen

- DIN EN ISO 75:

Kunststoffe – Bestimmung der Wärmeformbeständigkeitstemperatur- Teil 1: Allgemeines Prüfverfahren

- Teil 2: Kunststoffe und Hartgummi

- Teil 3: Hochbeständige härtbare Schichtstoffe und langfaserverstärkte Kunststoffe

- DIN EN ISO 306:

Kunststoffe – Thermoplaste – Bestimmung der Vicat-Erweichungstemperatur VST

Weitere Normen

- ASTM D 1525:

Standard Test Method for Vicat Softening Temperature of Plastics - ASTM D 648:

Standard Test Method for Deflection Temperature of Plastics under Flexural Load in the edgewise Position

Prof. Dr. Ines Kotter

Phone: +49 (0)3461 30889-70

Write e-mail