Tensile tests on polymers

In our accredited testing laboratory MPK, we can carry out tensile tests on plastics for you in a temperature range from -50 °C to 250 °C.

As a special feature, we can determine the Poisson's ratio at different temperatures. Another special feature is the determination of true stress-strain diagrams, for example for dimensioning tasks and constructive design.

With our decades of experience and thanks to extensive and up-to-date technology, we cover a wide range of standards and test methods, which enables us to offer solutions for almost all types of plastics such as thermoplastics, duromers, elastomers, thermoplastic elastomers (TPE, TPU, etc.) as well as films, laminates or fibre composites.

Please contact us for a quotation. We are also happy to help you with complex testing tasks or problems. If you would like to be tested according to a standard or factory/supply specification not listed here, we will be happy to clarify whether we can implement this.

Fundamentals

Tensile tests are one of the most frequently performed test methods in mechanical materials testing, along with the measurement of hardness. They are used to characterise the strength and deformation behaviour under uniaxial loading.

Tensile tests are performed

- on machined flat test specimens to determine the material behaviour under uniaxial tensile loading uniformly distributed over the cross-section,

- on notched test specimens for the simulation of multi-axial stress conditions (notched tensile test) and also

- on products such as wires, yarns, films, ropes, moulded components, parts or even component groups.

In the tensile test, the material behaviour

- under steadily increasing (shock-free) load – "classical" quasi-static tensile test,

- under constant static load – static tensile test,

- under alternating load to determine the cyclic stress-strain curve – LCF (Low Cycle Fatigue),

- at room temperature,

- at elevated temperatures,

- at low temperatures,

- at very low test speeds – creep tensile tests or also

- at increased test speeds – high-speed tensile tests

investigated.

The characteristic values determined in the tensile test

- form the basis for the calculation and dimensioning of statically stressed components and structures,

- are required for characterising the processing behaviour of materials,

- are used in quality control to assess the uniformity of production and

- are used in material selection for the comparison between materials and material states.

True stress-strain diagrams, which are mostly determined in tensile tests, are the basic requirement for demanding dimensioning tasks and the constructive design of complex polymer components using the finite element method (FEM). The construction of the true stress-strain diagrams is based on the determination of the actual and time-varying cross-sectional area as well as the varying initial gauge length.

The tensile tests to determine the apparent stress-strain diagrams can be carried out for almost all types of polymers such as thermoplastics and duromers, as well as laminates or fibre composites in the linear and non-linear viscoelastic range until the yield point is reached. By simultaneously determining the transverse contraction as a function of the longitudinal strain, the true stress-strain diagram and the characteristic values derived from it can be calculated with reference to the current cross-sectional area.

Sample preparation

- Injection moulding

- Machining

- Punching

- Notching: one-sided for SENT specimens (single edge notch tension) or two-sided for DENT specimens (double edge notch tension) for fracture mechanics tests

- Exposure to media or artificial ageing

Test conditions

- Test speed up to 1250 mm/min

- Temperature control from -50 °C to 250 °C

- Performing temperature ramps

- Standard climate (23 °C, 50 % humidity)

- Forces from 5 N to 50 kN

- Determination of Poisson's ratio, also possible in tempered conditions

- Performing short-term creep and short-term relaxation

- Carrying out cyclic tests (short-time tests, few oscillations)

- Testing of thermoplastics, duromers, elastomers, thermoplastic elastomers (TPE, TPU, etc.), films, laminates and fibre composites, among others

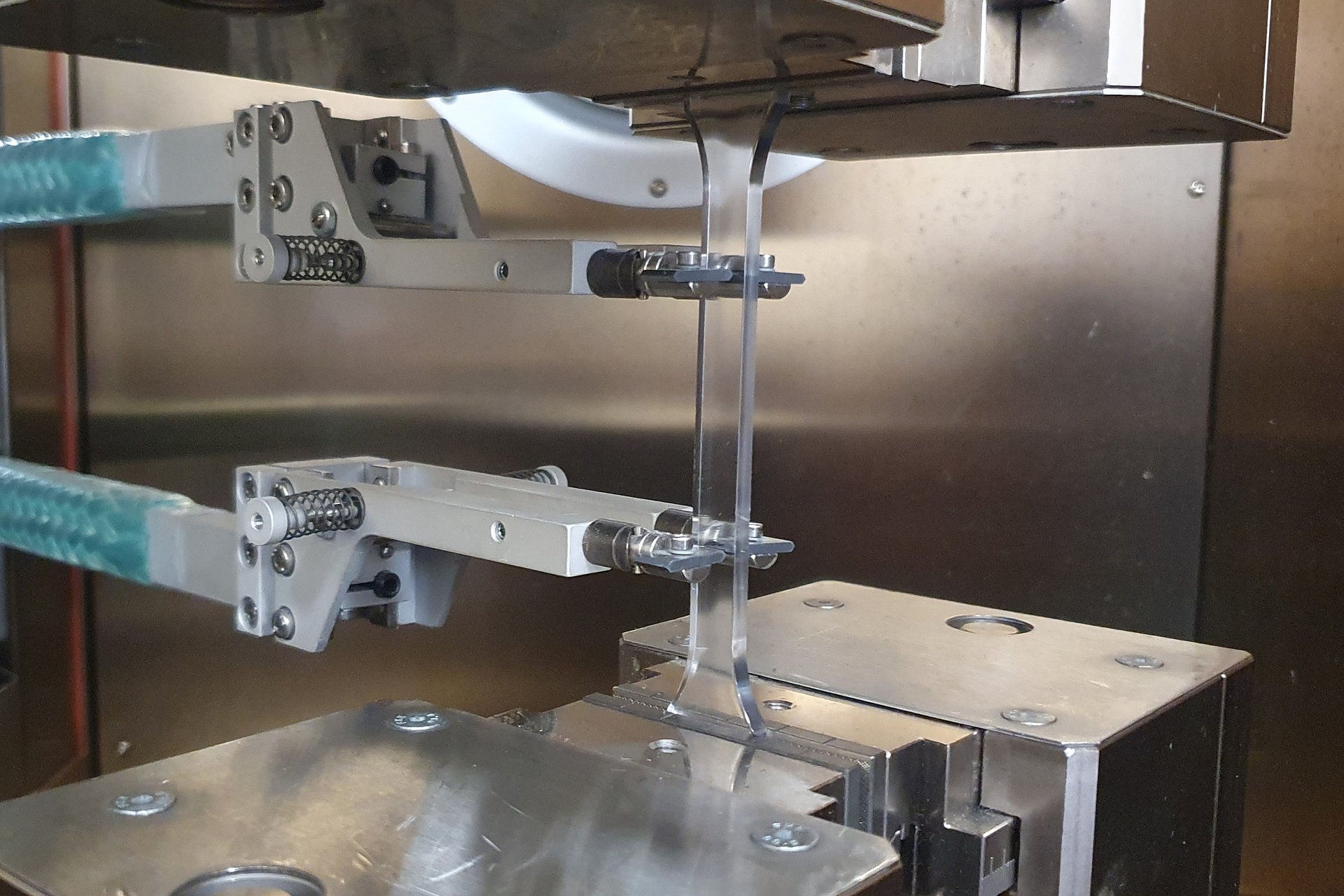

- Various clamps available according to requirements

Specimen types:

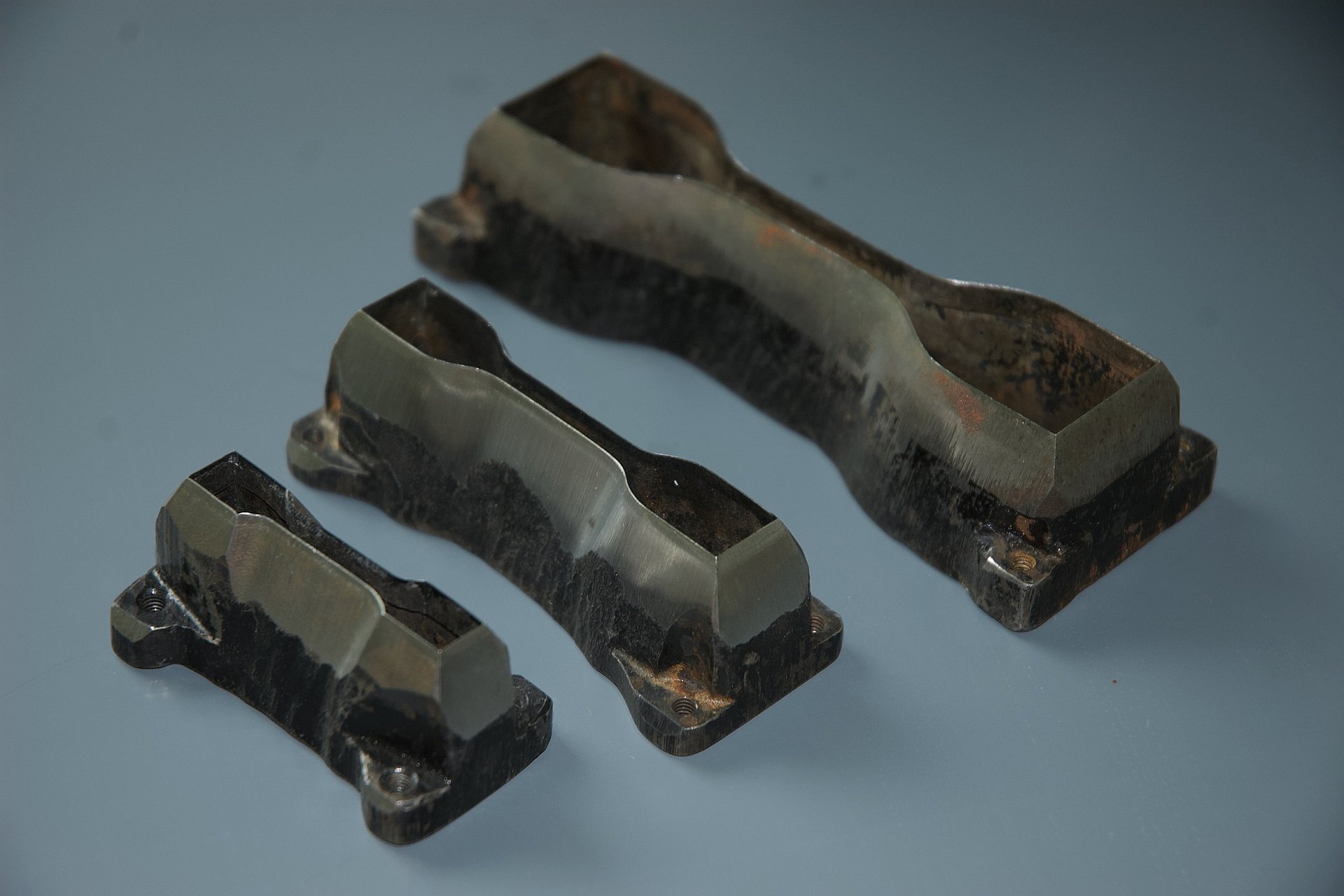

- DIN EN ISO 527-2: Type 1A, Type 1B, Type 1BA, Type 1BB, Type 5A, Type 5B

- DIN EN ISO 527-3: Type 1B, Type 2, Type 4, Type 5

- DIN EN ISO 527-4: Type 1A, Type 2, Type 3 (without centring holes)

- DIN EN ISO 527-5: Type A, Type B

- ISO 37: Type 1, Type 1A, Type 2, Type 3, Type 4

- DIN 53504: Type S1, Type S1A, Type S2, Type S3, Type S3A

Standards

Akreditierte Normen

- ISO 37: Rubber, Vulcanized or Thermoplastic – Determination of Tensile Stress – Strain Properties

- DIN EN ISO 527-1: Kunststoffe – Bestimmung der Zugeigenschaften – Teil 1: Allgemeine Grundsätze

- DIN EN ISO 527-2: Kunststoffe – Bestimmung der Zugeigenschaften – Teil 2: Prüfbedingungen für Form- und Extrusionsmassen

- DIN EN ISO 527-3: Kunststoffe – Bestimmung der Zugeigenschaften – Teil 3: Prüfbedingungen für Folien und Tafeln

- DIN EN ISO 527-4: Kunststoffe – Bestimmung der Zugeigenschaften – Teil 4: Prüfbedingungen für isotrop und anisotrop faserverstärkte Kunststoffverbundwerkstoff

- DIN EN ISO 527-5: Kunststoffe – Bestimmung der Zugeigenschaften – Teil 5: Prüfbedingungen für unidirektional faserverstärkte Kunststoffverbundwerkstoffe

- DIN 53457: Prüfung von Kunststoffen – Bestimmung des Elastizitätsmoduls im Zug-, Druck- und Biegeversuch (zurückgezogene Norm)

- DIN 53504: Prüfung von Kautschuk und Elastomeren - Bestimmung von Reißfestigkeit, Zugfestigkeit, Reißdehnung und Spannungswerten im Zugversuch

- DIN 65378: Luft- und Raumfahrt – Faserverstärkte Kunststoffe – Prüfung von unidirektionalen Laminaten – Zugversuch quer zur Faserrichtung

weitere Normen

- DIN 65469

Results

- Tensile modulus Et

- Poisson's ration µ

- Stress at yield, yield stress σy

- tensile strength σM

- strain at strength εM

- strain at break εB

- Stress-strain curve

Thermoplastics and duromers

Dipl.-Ing. Andreas Oluschinski

Phone: +49 (0)3461 30889-68

Write e-mail

Elastomers and films

Dr. Katja Oßwald

Phone: +49 (0)3461 30889-72

Write e-mail