Compression set

The compression set is a typical parameter for elastomers, thermoplastic elastomers (TPE) and sealing materials.

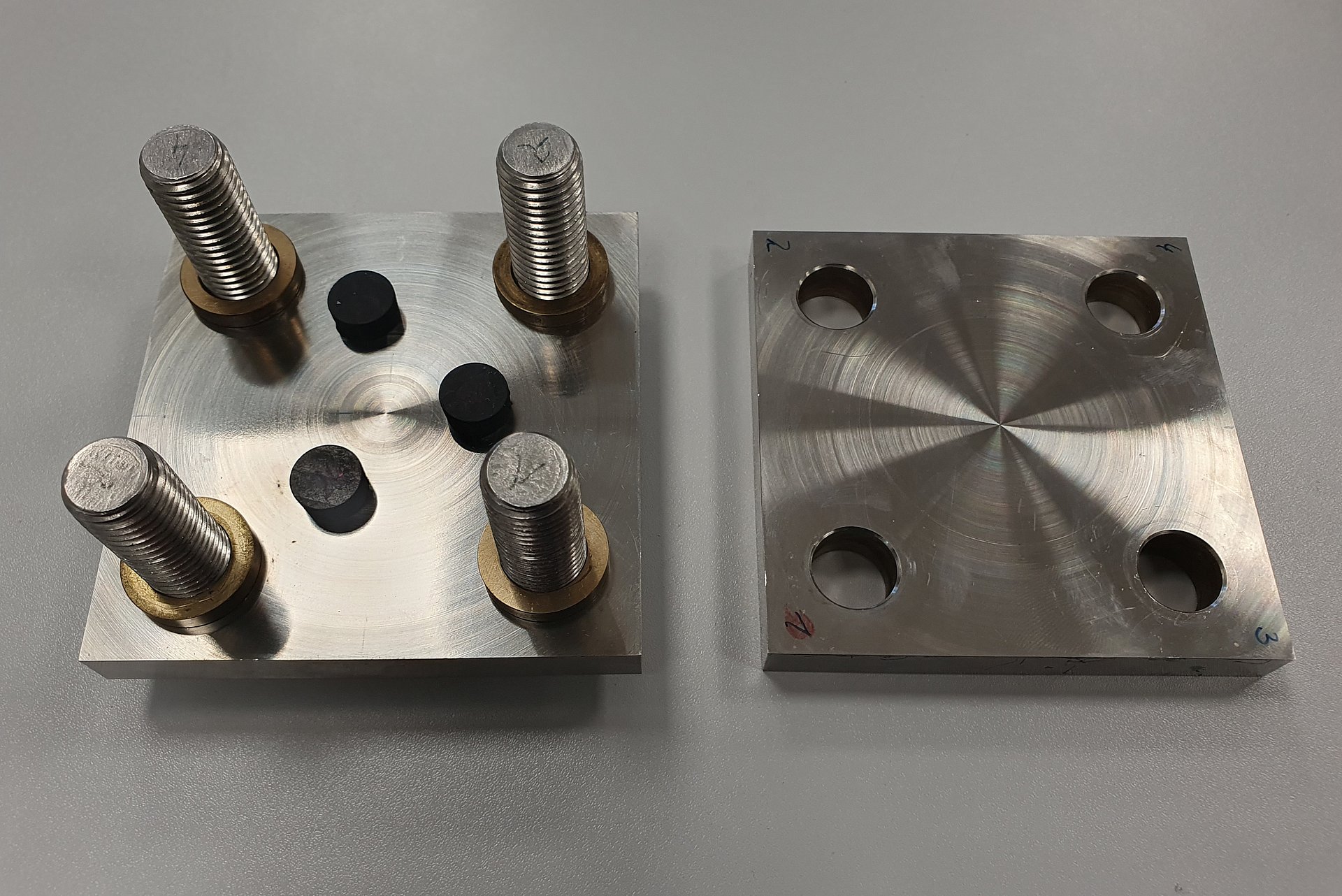

To determine the compression set, test specimens are compressed to a defined thickness, usually by 25 %, between two compression plates. This condition is then maintained at a specified temperature for a specific period of time. Afterwards, the deformation is released and the test specimens relax for a defined time. The residual thickness of the test specimens is then determined and the compression set is calculated.

This method is intended for elastomers that have a hardness in the range of 10 IRHD to 95 IRHD.

Fundamentals

Physical and/or chemical changes may occur during compression of the test specimens. These may prevent the elastomer from returning to its original thickness after relief. The magnitude of the change depends on the selected parameters of loading duration and temperature during compression but also during recovery.

If the compression set is determined at short stress times, usually 22 h and at elevated temperatures, it can be used as a measure of the degree of vulcanisation, as a means of material classification and to ensure compound quality. For longer exposure times, e.g. 1000 h and elevated temperatures, the ageing effect of the test specimens is included. If the compression set is determined for short exposure times and at room temperature, physical changes such as a rearrangement of the molecular chains and the fillers usually dominate.

Sample preparation

- If possible, plane-parallel plaques with a thickness of 2 mm or 6 mm

- Removal of test specimens from plates by punching circular specimens

- Specimen type B: thickness 6 mm, diameter 13 mm

- Testing of components such as O-rings or other sealing geometries possible

Test conditions

- Testing at room temperature

- Elevated temperatures up to approx. 300 °C possible

- Test specimen type B

- Method A: Cooling of the test specimens at standard climate on a wooden base

- Method B: Cooling of the test specimens at standard climate, then release from the pressure plates

- Method C: Loosening of the pressure plates, annealing at test temperature and then cooling at standard climate

Standards

Akkreditierte Normen:

- DIN ISO 815: Elastomere oder thermoplastische Elastomere – Bestimmung des Druckverformungsrestes

- Teil 1: Bei Umgebungstemperaturen oder erhöhten Temperaturen

weitere Normen:

- DIN EN ISO 1856: Weich-elastische polymere Schaumstoffe – Bestimmung des Druckverformungsrestes

Results

- Compression set

Dr. Katja Oßwald

Phone: +49 (0)3461 30889-72

Write e-mail